my projects in flashes

All pictures & images are real and belongs to my personal career.

Because of privacity rules in some of the companies will be not possible to show images related to Defense.

The Visualbookblog pretends to give only an small view in pictures that usually offer a better understanding of the lived behind the lines in the CV.

In any case only those people with enough experience in living abroad are able to deduce the great difficulty that suppose manage and improve in a different cultural mindset,specially in India.Here to look for a determined size of nut or washer in India is not like provide it in middle of Manhattan,install an scafolding probably means to cut dozens of bambu to create it manually ,and the costs always flight around 40% less than the usual the budget in any solution,that creates the hugh possibility to compromise the quality.In any case you are in the world competition for the business.You need to create your own way to demostrate your are in pole position.

My evaluation/proposal to reduce the carbon finger print in MahindraCIE .Inauguration of new electrical forklift area(looking for a clean company) Pune (India)

plant crane welding & preparation (checking assy of components) on site by supplier Kone

final welding & painting and load test. Kanhe II Pune (India)

automated scrapper one way with trap doors.Allocation & integration in PLC for functioning when system is working.Kanhe II Pune (India)

Destacker for raw material & robot picking to feed press (Installation and integration).

Kanhe II Pune (India)

Grippers fitting ,welding & manual testing ready to robot arm.Pune (India)

planned visit from the executive staff CIE AUTOMOTIVE in Europe & India to review the status of project on site.

from the left ,Mr Yudego (commercial Director),me (Country Project Manager),Narendra Gitay (Civil&Installations manager),Shantanu Parvati (COO Stampings India),Mr Ander Arenaza (Global CEO CIE Automotive),Kaul Romesh (CEO INDIA STAMPINGS),Oroiz (Global Controller)…..

inside the Quality Box,CMM Hexagon DEA Mercury with Advanced Axis Thermal Compensation system & measure software PC-DMIS Touch.

Blue light scanner ATOS (GOM)

Me in daily Fast Response Meeting for mind change,plant review,quick Issues solving,review of compromising cases,Quality/Safety/Productivity monitorizing in few words.

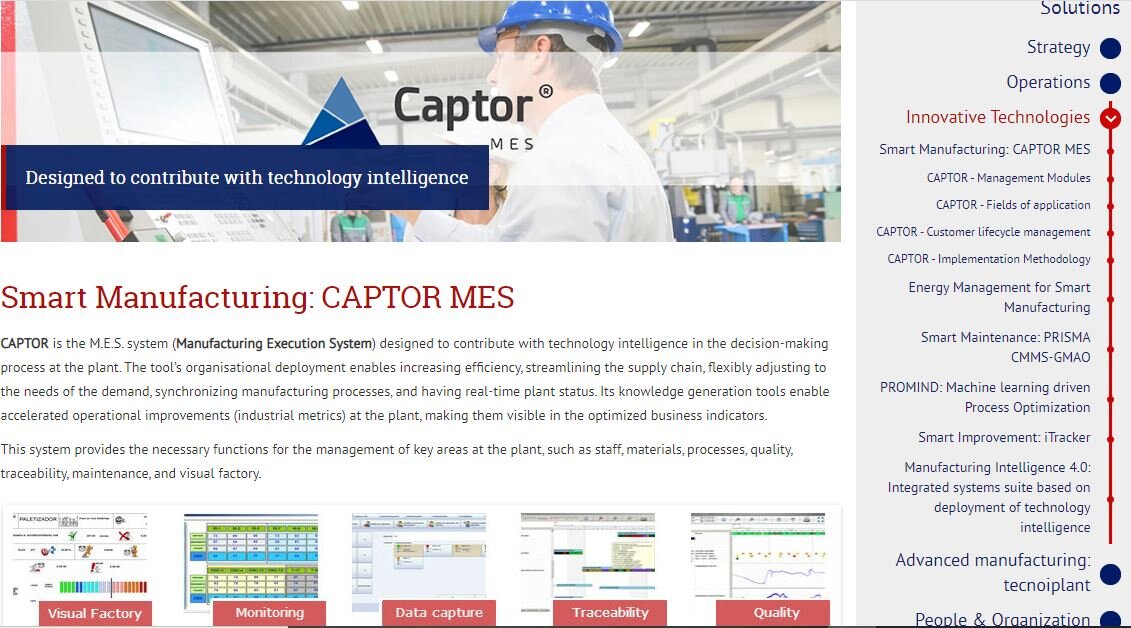

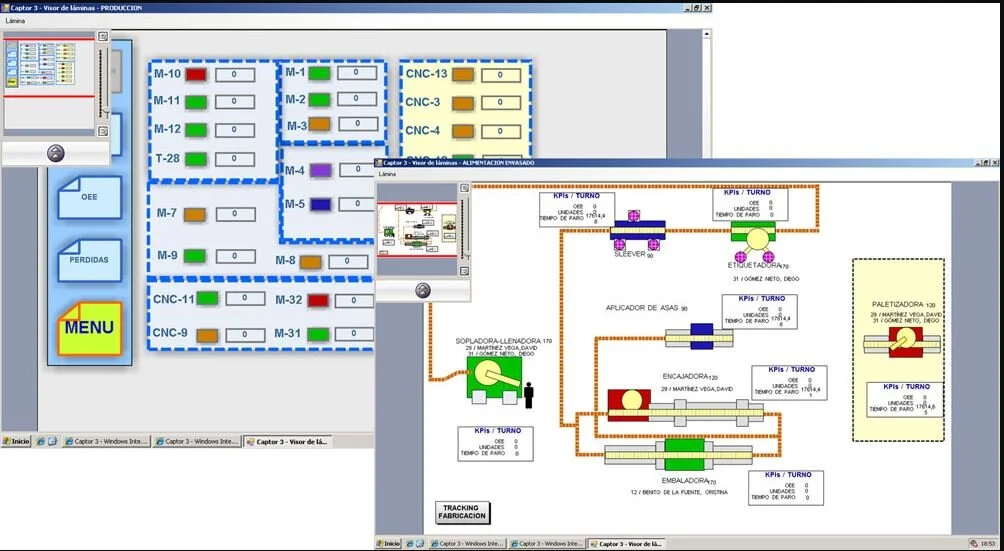

Implantation of CMMS (GMAO) ,computerized maintenance management information,global software for CIE AUTOMOTIVE for plants/business analysing system variables and key performance indicators enabling forecasting abnormal situations.

https://www.sisteplant.com/en/solutions/innovative-technologies/smart-manufacturing-captor-mes/

once the improving is done you have a complete access to all areas (machines-workers) in real-time to Production and plant operations control,Visual factory and KPIs,Quality and traceability,Usable products management (consumables),Knowledge management,Planning,Energy management and Customization.

the accessibility to the Captor System is possible in remote from each plant in case of a corporate version.

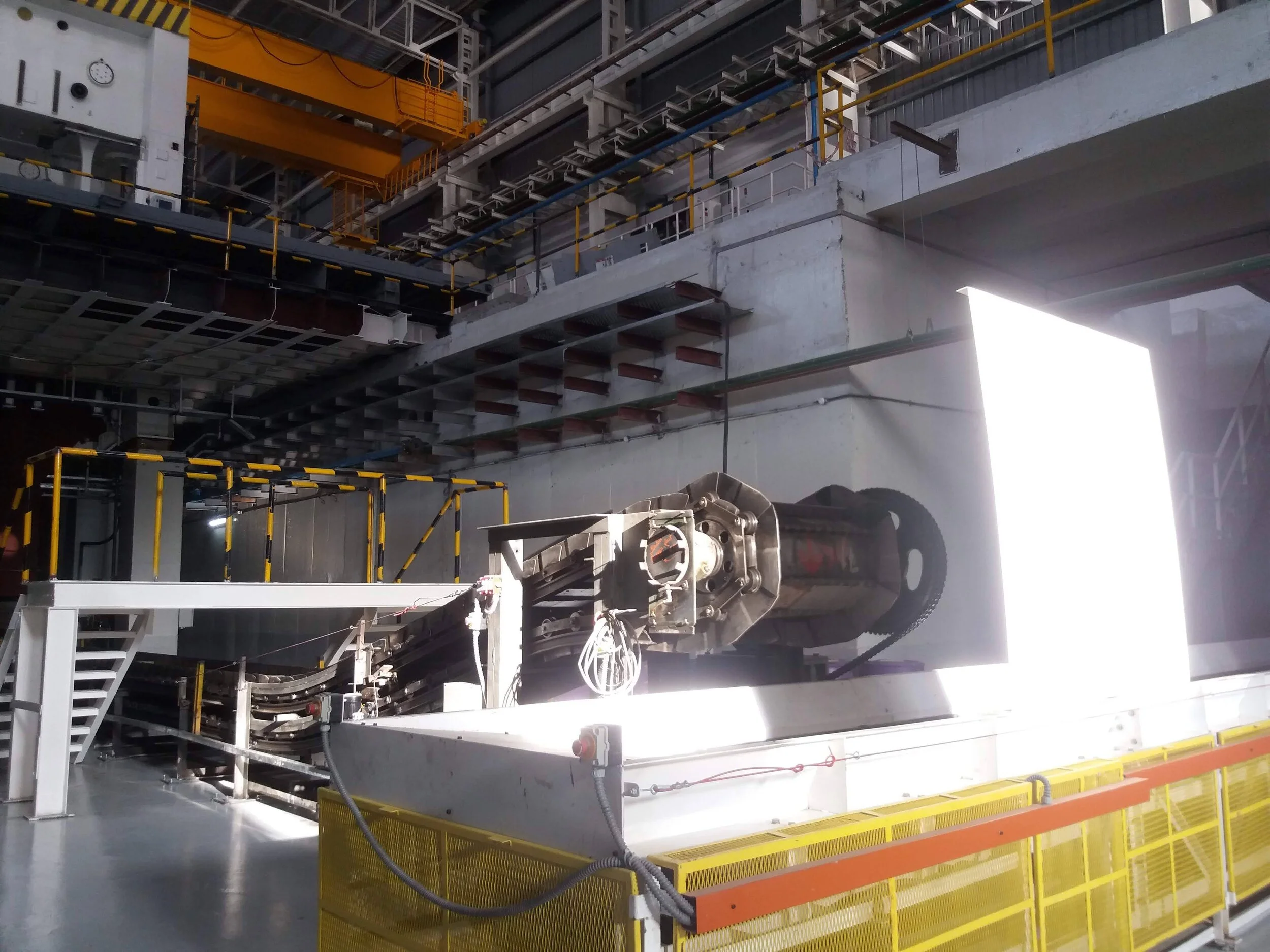

Kanhe II plant Project (final aspect ,ready to trials) 2017-2020 Pune (India),in charge of layout of plant,civil+eng execution project under VDA 6.3 Qualification System.

Actually the most efficience & productive line in the India portfolio of MAHINDRA CIE AUTOMOTIVE.

under my supervision & management with architect and civil/eng contractors initial Kanhe II project status 2018 Pune(India)

50% project (final concreting,presses pre-installation) Kanhe II Pune (India)2019

rails for moving bolster (press beds) laser alignment as per project drws,welding and concreting.

Kanhe II Pune (India) 2019

automated scrapper one way with trap doors.Allocation & integration in PLC for functioning when system is working.Kanhe II Pune (India) 2019

Siemens control & pannel install&integration.My participation was some indications in the definition of robot routines (positioning points,safety movements,assurance of the full equipepment during stamping procedure,allocation & centering of robot ,dies,presses,moving bolsters,etc…)

Kanhe II Pune (India) 2019

after 6 months in an isolated location in Maharastra,with big efforts from the team,my collaborators Antonio or Saulino (Estro Eng Naples) and my directives & continuous supervision on site of different areas the Line robots are ready to dance!!! ,for a high speed movement we require a fine tunning and best fit,the target is 6 spm (strokes per minute,the max in this type of press line).2020

the Qbox (Quality Box with Monitor indoor climate, light irradiation and air quality controlling) area,for CMM ,laser tracker,Scanning,etc…

one of my favourites and Team hits. Kanhe II Pune 2020

Scanning of gear (reverse engineering process).2019

3D recreation in CAD measurement module & results optimization and best fit to create a carbon copy of original part (gear).2019

Mahindra CIE AUTOMOTIVE Newsletter: Collaborative actions / Synergy Travels to push the company culture for Efficience and good practises in Productive methods.

Standard Workstation time control execution monitoring (Jaguar -Land Rover Birmingham UK) December 2016

Door lateral area to cover (Jaguar -Land Rover Birmingham UK)2016

Land Rover-Jaguar Plant Birmingham (FRONT/BACKrest of interior door pannel)

Hot Wrapping Cell fails detecting (plastic+leather)

Assy timming improvement (MTM - Method Time Measurement) Jaguar -Land Rover Birmingham UK 2016

hot wrapping manual tooling (Jaguar -Land Rover Birmingham UK)2016

Manual / Visual interior profile checking fixture (gap test).(Jaguar -Land Rover Birmingham UK)2016

Mercedes Benz plant in Vitoria (Spain).No photos were permited inside plant for privacity policy.

New extension Layout definition for rump up of manufacturing volume and execution of project,new industrials installations (HOTforming cells).

my rol: Implant & optimizing of work cells, presses management, contract management comprising mechanical, electrical, and hydraulic and final test/validation of product.

Below one press with foaming robot in contractor location for preliminary trials in Milano. 2017

indicators for daily review (fails & non conformities)(Jaguar -Land Rover Birmingham UK)2016

on top,Hot Forming lower mould configuration drawing for analysis in detection of issues in exact blocks,testing during the moulding process on site,confirming of correspondence areas with defects in part,repositioning of spare blocks and alignment and validation of new product)

down left,preliminary sketch/notes during analysis in detection of fails for solving (marks in product,down on the right)

Jaguar -Land Rover Birmingham UK 2016

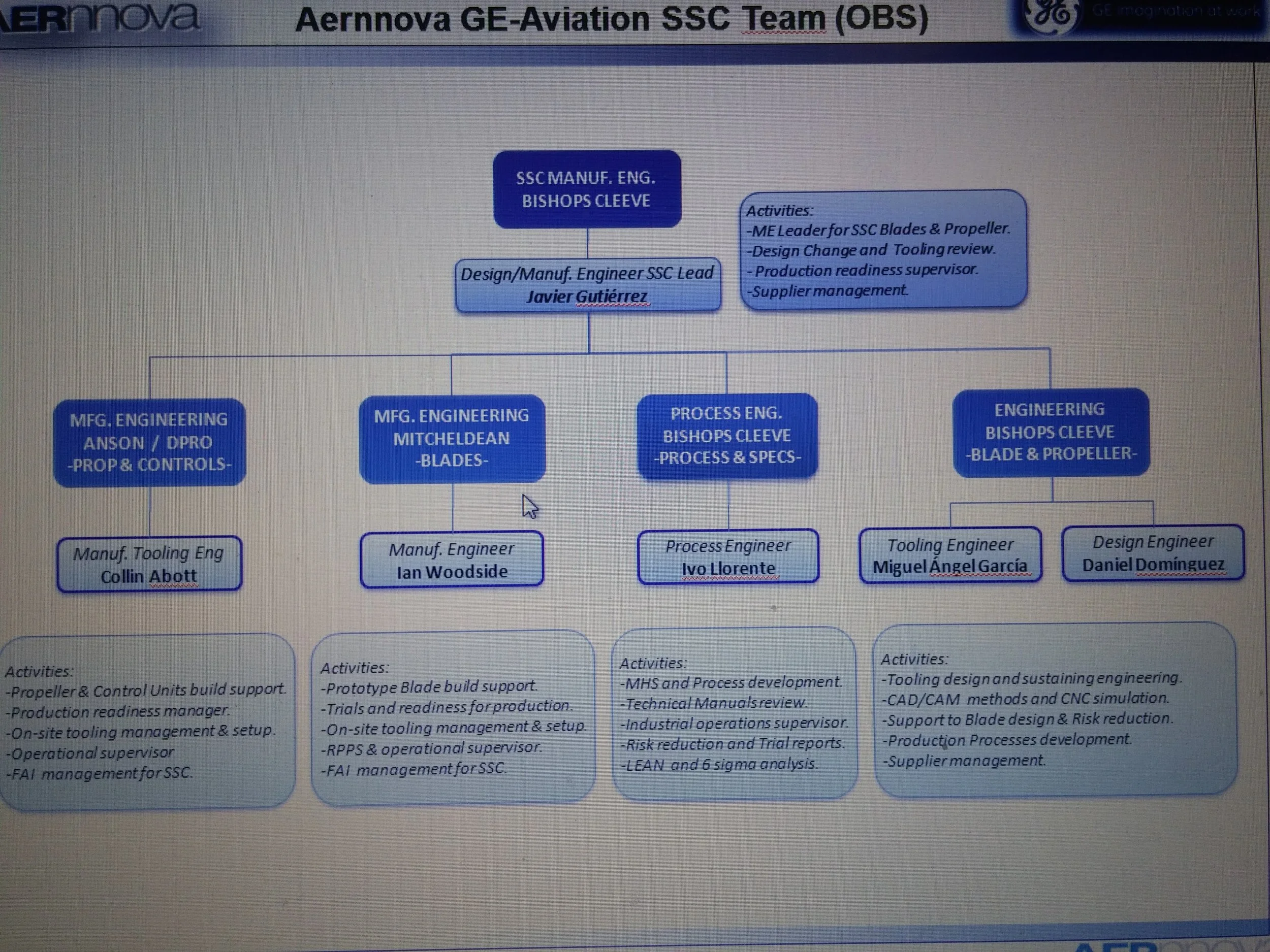

GENERAL ELECTRIC AVIONICS.TOOLING MANUFACTURING engineering department leader of a team of 10 design engineers to collaborate on a project for TEXTRON, an American supplier to the US NAVY to drive and develop a program called SSC (design and manufacture of the rear drives of the improved version of the LCAC , assault hovercraft for the American Army, being a strategic project for GE.My presence tryied to give added value to the engineering department of tooling manufacturing for assembly and execution of processes in coordinating with the Project Managers of GENERAL ELECTRIC AVIONICS reviewing the progress of jobs(drws), monitoring of fabrication orders in suppliers and daily tracking of toolings in progress. CHELTENHAM (GLOUCESTERSHIRE) UK 2015

project organization chart.UK 2015

In 2001 a medium-sized company called Jesda (with more than 25 years of experience in precision machining) suggested me to participate in a new model,trying to be one of the best suppliers of tooling for medium-sized aerostructures, serving clients such as Aernnova , Airbus or Alestis at your plants in Spain at that time. With an ambitious target in near to 3 years with th e contribution of the general mangement and some strategic investments in Technology the capacity and sales volume of the company reach to duplicate your percentage of growth in 5 years.

As a Head for Design and Manufacturing of aeronautical tools and elaboration of machining processes for ultra complex parts,Positioning tools/control tools,checking fixtures.

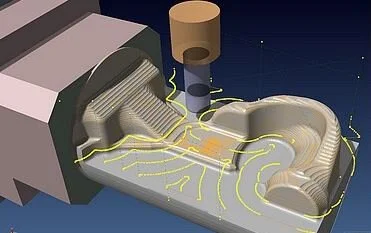

Expertise in Catia v4 / v5, Unigraphics, Cimatron, Tebis and Autocad systems. Technical feasibility studies of pieces,design or in conjunction with External engineering for product development.

Part/Tool development through digitization with laser Tracker,CMM and later product modeling. Development of projects for aeronautical tools for trimming, drilling, molding, Assembly Aerostructures and stands, etc ...for A380,A350,A330,A320,A318,A400M,EUROCOPTER programs

My principal rols:

MANAGER OF TECHNICAL AND QUALITY DEPARTMENT (IMPLEMENTING OF ISO9001),INTERNAL AUDITOR.

REVIEW OF CUSTOMER DRAWINGS AND SPECIFICATIONS IN COORDINATION WITH PRODUCTION MANAGEMENT.

PREPARATION OF PROGRAMS (CIMATRON-CATIA) & PROCESSES DEFINITION / ROUTE MAP OF MACHINING JOBS/ PLANNING OF THE REALIZATION OF THE PRODUCT FOR CLIENT.

KICK OFF OF A NEW PRODUCT/TOOLING IN COORDINATION WITH GENERAL MANAGEMENT,ADMINISTRATION AND LOGISTICS.

MONITORING OF CUSTOMER ORDERS.

QUALITY MANAGEMENT ACTIVITIES (CERTIFICATIONS,CONTROL PLANS,CALIBRATING PLANS and INTERNATIONAL STANDARDS DATABASE).

PERFORM THE IMPLEMENTATION OF THE ERP SYSTEM (DEFINITION ,IMPLANTATION,TESTING AND FOLLOW UP).The Software based in data capturing in plant (MICRO PROCESS DATA SHEET).

PREVENTIVE MAINTENANCE OF THE INFRASTRUCTURE (IMPROVING OF PREVENTIVE SOFTWARE TO MONOTORIZE DAILY/WEEKLY/MONTHLY,ANNUAL REVISIONS/CHECKS).

IDENTIFICATION OF PROCUREMENT NEEDS AND PURCHASE ORDERS MANAGEMENT.

DIRECT DEAL WITH CUSTOMERS AND SUPPLIERS (AIRBUS,AERNNOVA,ALESTIS GROUP,ALLIO,COMAU,CERN,DEDIENNE AEROSPACE,COMPOSITE INDUSTRIE,MIKRON,SACHS,Thyssenkrupp….

www.jesda.es

Sample of aero structure for pre-assy of fuselage sections in OEM plant made in JESDA.Measurement by FARO LASER TRACKER. 2011

1998-2000 EGAÑA PLANT-CIE AUTOMOTIVE (Berriz-Bizkaia/Spain)

Product Engineering Designer.

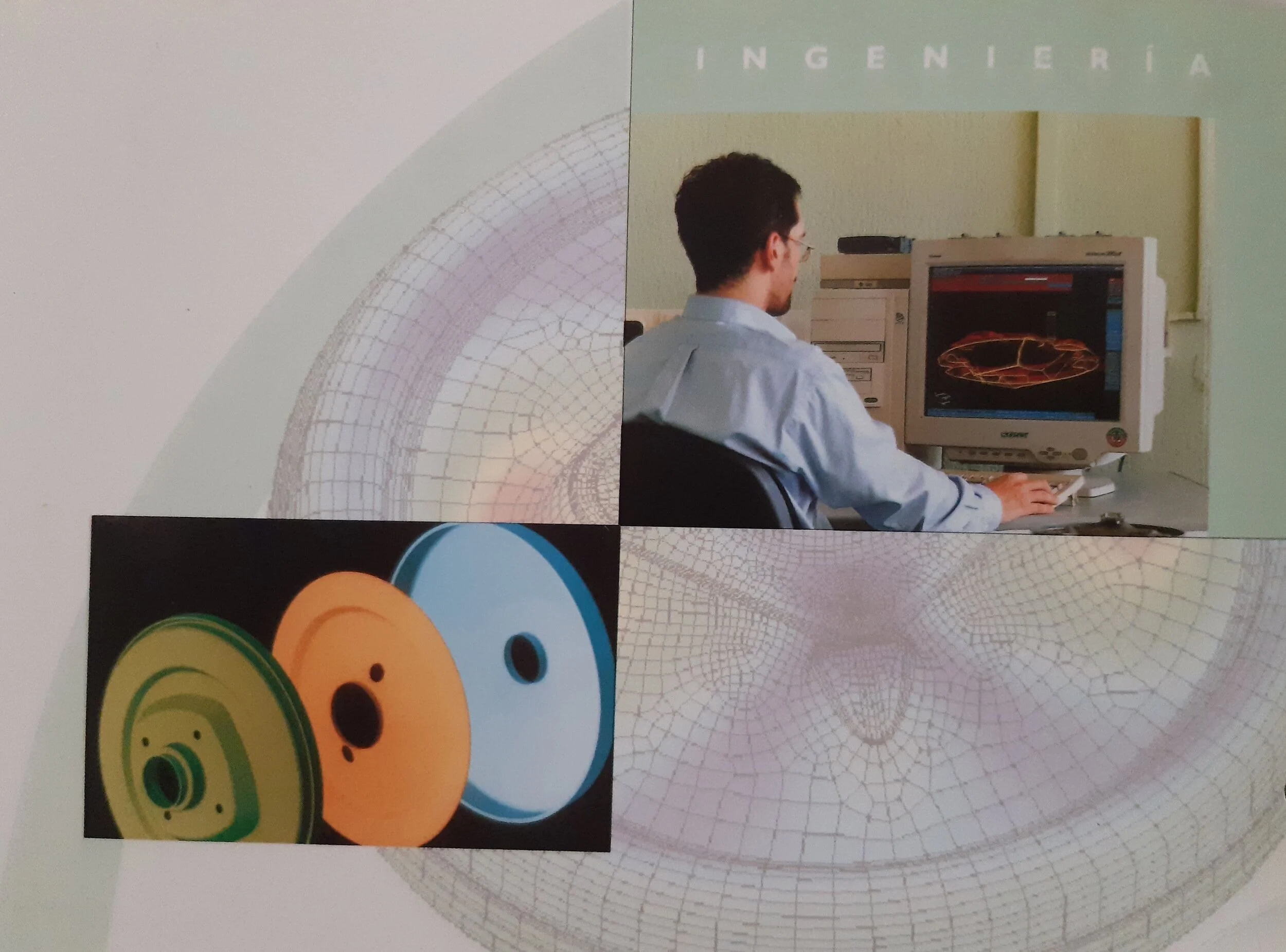

Hugh change in the productive way improving the evolution from manual methods to digital.Develop of CAD/CAM in tool room department with CIMATRON and CATIA V4 softwares.

Responsible for the automation of dies manufacturing processes in the plant.

Application for new parametric design techniques in 3D Transfer Dies.

Collaboration in the development of parts for the current Mini Cooper, developing the rear braking system using 3D tools with the engineers of the Lucas plant in Manchester.

Technical and commercial relationship with important customers: Antolín, Bosch, Continental, Daf, Delphi, Fafecia, Filfrauto, Gnk, Schaeffler Group, John Deere, Kyb, Lear, Nexteer, Nsk, Paulstra, Pierburg, Trellborg, Trw, Valeo, Visteon , Woco, Zf.

me in CIE AUTOMOTIVE - EGAÑA PLANT.Ellaboration of Programs (Simulation 3D) for matrix component.1998-2000 Berriz (Bizkaia/Spain)

1996-97 TAM GROUP company envolved in Full-cycle projects of equipped aerostructures and electrical systems onboard; Design, manufacture and assembly of equipped structures; Design and manufacture of tooling; Design and manufacture of electrical systems; Full-cycle projects of components in RTM and LRI composite materials; FAL support in mechanical integration and systems onboard; Industrial measurement and maintenance of assembly lines; Integrated Logistics Support (ILS) and technical publications.

ROL:Coordinator of design and manufacturing through CNC programming (CATIA V4) in machining centers, 5,4 and 3 axis milling machines.

Manufacture of big size parts with complex geometries and precision finishes in special alloys INVAR,INCONEL,TITANIUM).

Definition of postprocessors.

(IMAGE: Armored helicopter lateral ,5 mm thickness,anti-deformation machining strategy using ribs,centering system high precision tooling balls,raw material from cubic block)

Principal customers: EADS (actually AIRBUS GETAFE), CESA, GAMESA and ITP

Operability in the company: -Engineering calculations. -Realization of technical specifications. -Preparation of technical offers -Performing procedures for the mechanical engineering department. -Data Base Programs for engineering documentation management ¬ -Management of AUTOCAD V12 and CATIA for the realization of construction layouts/drws and for the realization of drilling programs for execution in Galindo´s factory (Sestao) -Implementation of IS0 9001 in the company. -Inspection and supervision jobs in Factory or contractors facilities (control of the manufacture of parts in their different manufacturing-welding processes, painting, NDT, packing list, logistics management).

kaplan Turbine for shipping to Venezuela (Central de Macagua II).1991.B&W Galindo Factory Sestao (Bizkaia) after completition of manufacturing and final testing/validation trials.

In charge of FAI (FIRST ARTICLE INSPECTION)

Cooperative company belonging to the Mondragón Group dedicated to the Design and Manufacture of Dies and Systems for the Automotive Sector.

Technical Design (3D) and Programming CAM via EUCLID.

BASQUE COUNTRY.IGORRE (BIZKAIA) 1989-91

Rouhgness procedure (Z level machining) ,lifting hooks integrated in bottom mould.Vericut Simulator.BATZ 1990

After the period 1988-1989 post to execution of Master in Manufacturing Engineering in IFOA (Institute for the Practical Training of the Company) Apprentice in TRANSMITTAL BONFIGLIOLI in the facilities located in Forli (Bolonia) Italy ,3 months in Machining area for execution of gears for rotative diggers.